Jakarta International Stadium

Fabritecture was commissioned for the design, supply, fabrication and supervision of installation for a transparent ETFE roof as part of the new 82,000-seat Jakarta International Stadium, which opened to the public in April 2022.

Hosting 82,000 spectators, Jakarta International Stadium is the first retractable roof stadium in Indonesia, the largest (by capacity) stadium in Asia and second largest retractable roof stadium (by capacity) in the world, trailing only AT&T Stadium in Arlington, TX. The venue is also the first in Indonesia to also be approved as a Platinum Green Building to use the Green Building Council Indonesia's GREENSHIP Rating Tool (GBC Indonesia).

Standing 73m tall, the spectacular stadium offers 360-degree sky views of the city and the ocean from the stadium's rooftop sky view platform.

The stadium was built to be the finest arena in Jakarta for local and international football games as well as various entertainment.

Designed by PDW Architects, the stadium features a retractable transparent roof that closes when fans need weather protection and opens when the weather permits.

Fabritecture was contracted to design, fabricate, supply, and supervise the installation of the ETFE roof cladding, as well as the ridge and eave flashings.

ETFE single skin was chosen as the cladding material to allow the maximum light transmission into the stadium for the best spectator experience.

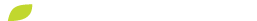

The fixed ETFE roofing on the outer rim of the roof covers 8,908m2 in plan area, while the retractable internal roof covers approximately 11,200m2, for a total area of 20,108m2. Both components of the roof are supported by a lightweight steel spaceframe.

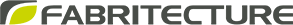

Fabritecture designed the fixed roof panels to be 300 um transparent ETFE supported by stainless steel wires at 1m centers in sealed ETFE pockets. The retractable roof ETFE panels were similarly made of 300 um transparent ETFE, supported by stainless steel cables. The retractable roof design specified two 'zones,' with the stainless steel support wires spaced at 500mm to 1m intervals.

What is Unique About the Project?

Given the sheer height of the roof of this stadium, great care had to be taken in the installation which was managed by Fabritecture. To support this process, Fabritecture developed a comprehensive installation methodology for both the inner ring fixed roof and the retractable roof modules.

The installation was supported by work platform nets, with the front edge of the ETFE secured to the nets' steel beams. The panels' back edge was mounted first from a metal roof.

To effectively manage water runoff from the stadium roof, particularly during monsoon season, Fabritecture designed the roof to be sawtooth in nature (with ridges and valleys at 10 degree slope) and added sumps and tailpipes at the end of each valley for water capture.

The single-layered ETFE cladding installed on the 73m high rooftop of the award winning Jakarta International Stadium provides a spectacular crown for this 82,000-seat stadium. With dramatic night time lighting, this stadium provides an amazing sporting and entertainment venue for locals and international visitors alike.

FABRITECTURE

Over the last 20 years, Fabritecture has designed and constructed hundreds of highly complex projects that involve intricate steel geometry and mostly fabric cladding. In recent years, we have transferred our skills and knowledge into projects involving Architectural Metals. Fabritecture has a well-developed supply chain for delivering steel and aluminum via our Hong Kong based procurement office.

To deliver our Architectural Metals projects, Fabritecture utilizes our established in-house project management experts and systems, engineers who specialize in 3D modelling software, and selected capable suppliers around the world.